Making the most of Performance: The Relevance of Genuine Komatsu Undercarriage Parts

Making the most of Performance: The Relevance of Genuine Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Parts for Heavy Equipment

Quality undercarriage parts play a substantial role in ensuring the smooth operation and durability of heavy machinery. In this conversation, we will certainly discover the significance of spending in top-notch undercarriage parts, common wear difficulties dealt with by heavy equipment operators, the advantages of prompt substitutes, standards for picking dependable providers, and vital upkeep pointers to expand the life-span of undercarriage components.

Significance of High Quality Undercarriage Components

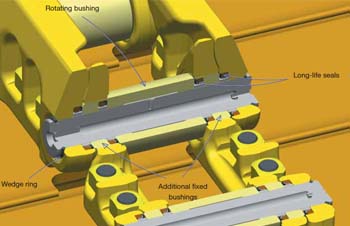

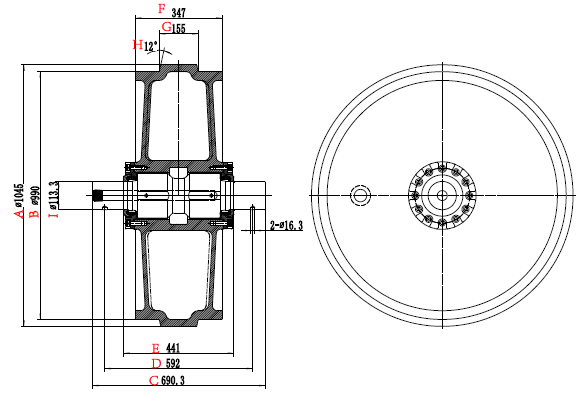

Quality undercarriage parts are vital parts in making certain the toughness and efficiency of hefty equipment. The undercarriage of equipment such as excavators, bulldozers, and track loaders plays a crucial duty in supporting the maker's weight, giving security on different terrains, and taking in the effect of uneven surfaces. By buying top notch undercarriage components, operators can substantially prolong the life expectancy of their machinery and minimize the risk of unanticipated breakdowns.

One key advantage of making use of quality undercarriage parts is the improvement of overall maker efficiency. Sturdy tracks, gears, rollers, and idlers reduce friction and guarantee smoother motion, inevitably causing raised performance and efficiency on work websites. In addition, reliable undercarriage parts lessen downtime for upkeep and repair work, allowing drivers to maximize their functional hours and job due dates.

Usual Undercarriage Use Issues

Advantages of Timely Replacement

One secret benefit of prompt undercarriage part substitute is boosted machine uptime. By replacing used parts prior to they fall short, the danger of unexpected break downs is decreased, decreasing downtime for fixings and maintenance. This proactive technique not only keeps the hefty equipment functional but also prevents potential damage to other elements that could result from a failing undercarriage.

Moreover, replacing undercarriage parts Click This Link quickly can enhance total performance. A well-kept undercarriage ensures ideal device performance, allowing for smoother operation and greater effectiveness in finishing jobs. This, subsequently, brings about boosted task site productivity and cost financial savings by avoiding delays and disruptions brought on by underperforming equipment. Spending in timely undercarriage component replacement is a proactive method that pays off in terms of boosted performance and reduced operational prices.

Selecting the Right Undercarriage Distributor

Picking the proper undercarriage provider is a critical choice that considerably impacts the efficiency and maintenance of hefty machinery. When picking a vendor for undercarriage parts, numerous elements have to be thought about to ensure optimum efficiency and cost-effectiveness. A distributor that provides a wide choice of undercarriage components for different hefty machinery brand names and models can be helpful as it provides a lot more options to satisfy details needs.

Additionally, reviewing the provider's customer care view it now and support look at this now is critical. A supplier that uses excellent customer support, fast response times, and technical aid can help reduce downtime and make certain smooth operations. Cost is also a considerable variable to consider; nevertheless, it must not be the single determinant. When picking the right undercarriage vendor for heavy equipment, stabilizing integrity, top quality, and cost-effectiveness is crucial. By very carefully reviewing these variables, you can pick a vendor that satisfies your demands and adds to the efficient performance and upkeep of your hefty equipment.

Upkeep Tips for Extended Life Expectancy

To make sure an extensive life-span for hefty equipment undercarriage components, applying an aggressive upkeep regimen is crucial. Spending in top quality undercarriage components from reputable suppliers is equally important for ensuring longevity. By following these upkeep pointers faithfully, hefty equipment owners can optimize the performance and durability of their undercarriage parts, inevitably lowering downtime and functional expenses.

Conclusion

In conclusion, quality undercarriage components are necessary for the effective procedure of heavy equipment. Prompt replacement of worn components can stop expensive downtime and maintain optimum performance. Choosing a reliable supplier and adhering to appropriate maintenance techniques are essential to ensuring the expanded life expectancy of undercarriage components. By resolving typical wear issues and purchasing top notch parts, hefty machinery drivers can make best use of efficiency and minimize upkeep costs.

Excessive wear and tear on undercarriage components of hefty machinery can lead to significant functional difficulties and increased upkeep expenses. Regular examinations, appropriate maintenance, and prompt replacements of used undercarriage components are important to mitigate these typical wear problems and make certain the ideal functioning of hefty machinery.

A distributor that provides a wide choice of undercarriage parts for different heavy equipment brands and designs can be advantageous as it supplies much more alternatives to meet details needs.

By adhering to these maintenance ideas vigilantly, hefty machinery owners can maximize the performance and longevity of their undercarriage parts, inevitably reducing downtime and functional prices.

Report this page